Email:info@ahsanxin.com Phone: +86-15655584855(WeChat) WhatsApp: +86-13013118515

Views: 14 Author: Brian Gao Publish Time: 2025-09-19 Origin: Site

In the world of modern metal fabrication, efficiency, precision, and flexibility are paramount. While different machines can perform individual tasks, the true magic happens when advanced technologies work in perfect harmony. The combination of a laser cutting machine and a CNC press brake represents one of the most powerful partnerships on the shop floor, forming the backbone of a highly efficient and agile manufacturing process.

This article explores how these two machines complement each other to create a seamless workflow from a flat sheet of metal to a complex, three-dimensional finished product.

The Indispensable Roles of Each Machine

First, it's essential to understand the unique strengths each machine brings to the table.

Laser Cutting Machine: The Master of Intricacy

A laser cutter uses a high-powered, focused laser beam to melt, burn, or vaporize material. Its key advantages include:

1. Unmatched Precision: It can produce incredibly complex and intricate shapes with tight tolerances.

2. Excellent Edge Quality: Lasers leave a clean, burr-free edge that often requires little to no secondary finishing.

3. Non-Contact Process: The tool (the laser beam) doesn't wear out from contact, ensuring consistent quality and eliminating tooling costs for cutting.

4. Flexibility: Design changes are simply a matter of updating a digital file (CAD), making it ideal for prototyping and high-mix, low-volume production.

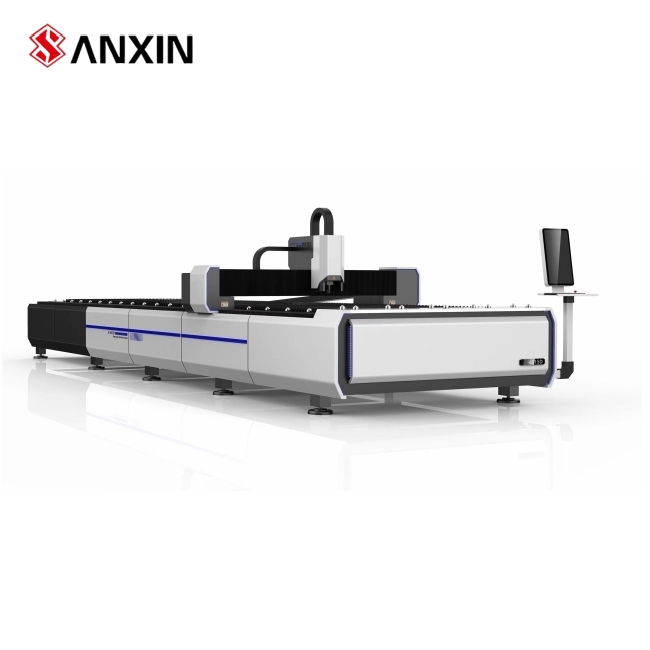

Sanxin Laser fiber cutting machine

CNC Press Brake: The Artisan of Form

A CNC press brake is used to bend and form the flat, laser-cut parts into their final 3D shapes. Its modern CNC (Computer Numerical Control) system provides:

1. High Bending Accuracy: CNC controls ensure every bend is exactly to the programmed angle and dimension, repeatably.

2. Complex Forming Capabilities: It can create multiple bends on a single part with different angles and geometries.

3. Automated Tooling: Modern brakes can automatically select the correct punches and dies, drastically reducing setup time between jobs.

Sanxin PSB11032K with advanced Delem DA53TX system

The Synergistic Workflow: From Digital Design to Finished Product

The synergy between these two machines is not just about using them sequentially; it's about a fully integrated digital process.

Unified Digital Design (CAD): The process begins with a 3D model of the part designed in Computer-Aided Design (CAD) software. This single model contains all the information needed for both cutting and bending.

Precision Cutting: The CAD file is translated into instructions for the laser cutter (often via CAM software). The laser meticulously cuts the part's external contour and any internal features—holes, slots, or cutouts—with extreme precision. Crucially, the laser can also engrave or etch reference marks and bend lines directly onto the part.

Seamless Bending Preparation: These laser-etched bend lines are a game-changer. They provide a visual guide for the press brake operator, simplifying positioning and eliminating measurement errors. The CAD data from the same model is also used to program the press brake, defining the bend sequence, angles, and required force.

Accurate Forming: The operator places the laser-cut blank onto the press brake, aligning it with the laser-etched marks. The CNC press brake then executes the programmed bend sequence with pinpoint accuracy. The clean, precise edges from the laser cutter ensure the part sits correctly in the brake's tooling, leading to a perfect bend every time.

Key Benefits of the Laser-Bending Combination

1. Reduced Lead Times: The digital thread from CAD to CAM eliminates manual drafting and measuring steps. Laser etching of bend lines drastically reduces setup and alignment time on the press brake.

2. Enhanced Accuracy and Quality: Using a single digital model for both processes eliminates cumulative errors. The precision of the laser-cut part ensures a perfect start for the bending process, resulting in a higher-quality final product.

3. Design Freedom & Complexity: Manufacturers can easily produce designs that were once considered too complex or expensive, fostering innovation.

4. Lower Labor Costs: The process requires less skilled manual labor for measuring and setup, allowing operators to focus on supervision and quality control.

5. Improved Material Utilization: Nesting software used with laser cutters optimizes the layout of parts on a metal sheet, minimizing waste and saving material costs.

The laser cutting machine and CNC press brake are designed for any serious metal fabrication manufactuers. When integrated through a digital workflow, they create a streamlined, highly accurate and remarkably flexible manufacturing cell. This partnership empowers metal fabricators to meet the demands of today's market.