Email:info@ahsanxin.com Phone: +86-15655584855(WeChat) WhatsApp: +86-13013118515

Views: 12 Author: Brian Gao Publish Time: 2025-09-11 Origin: Site

The Art and Science of Bending: Briefly introduction of Press Brake Operation

In the world of metal fabrication, few machines are as fundamental and trans-formative as the press brake. This powerful machine is the cornerstone of shaping sheet metal into the myriad of forms we see in everyday life—from the chassis of a computer and the body of an automobile to the structural frames of modern architecture. The process of bending metal on a press brake is a fascinating interplay of raw force, precise engineering, and skilled craftsmanship. It is both an art and a science.

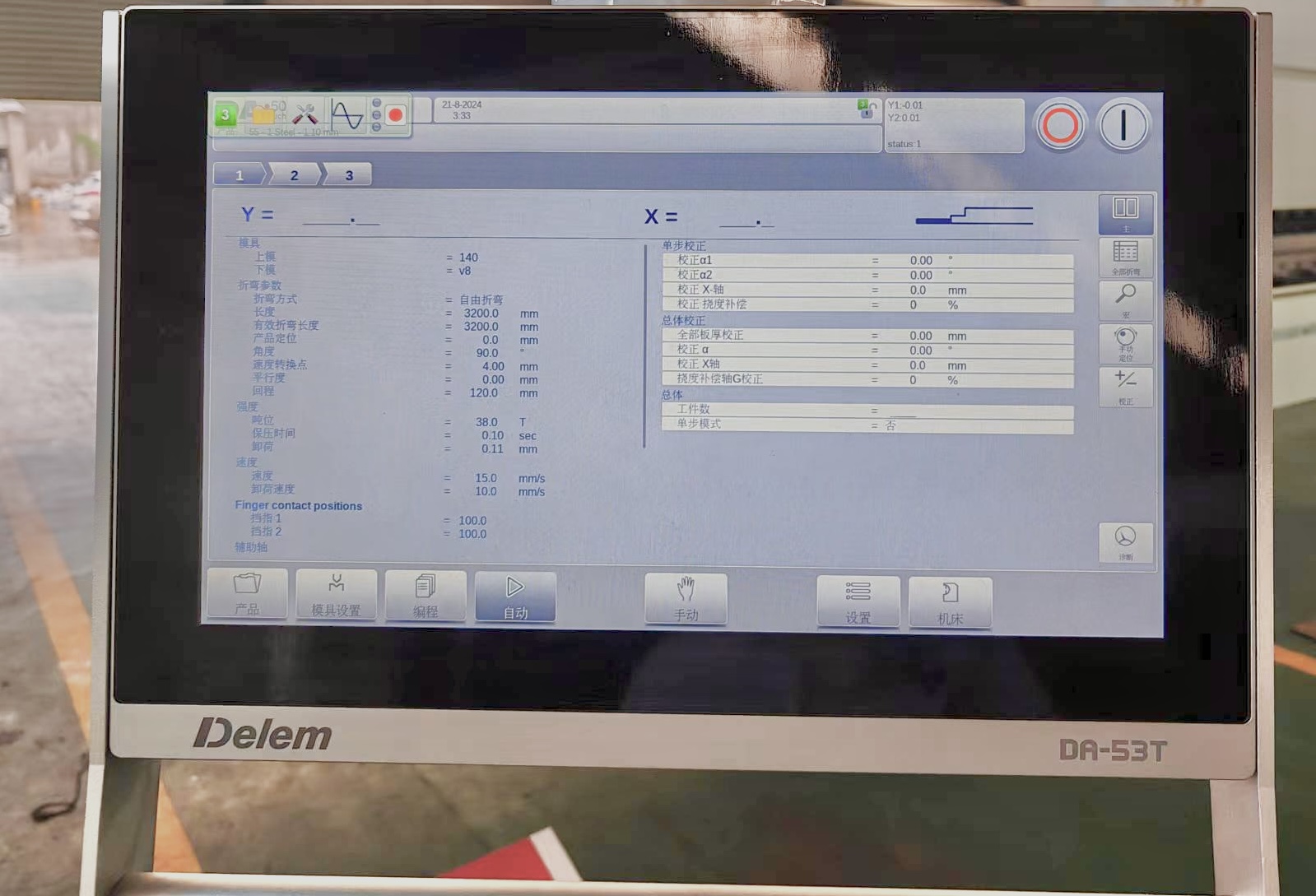

Sanxin PSB series CNC press brake with Delem DA69T system

At its core, a press brake is a machine that bends metal sheet and plate. The basic principle involves two key components: a punch attached to the upper ram and a corresponding die fixed on the lower frame. The sheet metal is positioned between them, and upon activation, the ram forces the punch down, pressing the metal into the die cavity to create a precise bend. While the concept sounds simple, the execution requires meticulous attention to detail to achieve accurate, consistent, and high-quality results.

The journey of a single bend begins long before the machine is activated. It starts with engineering and planning. Using the material’s properties—specifically its tensile strength and thickness—the operator must calculate the required tonnage (force) to achieve the bend without damaging the machine or the part. Crucially, they must also determine the bend allowance and bend deduction. These are mathematical calculations that account for the material’s stretching and compression during bending, allowing the operator to know exactly how much flat material is needed to achieve the desired final dimensions after bending. Modern press brakes often have advanced CNC systems with software that automates these complex calculations, but understanding the underlying principles is also important.

The setup phase begins when all the calculations are done. This involves selecting the correct punch and die. Meanwhile, the choice of tooling is also important. The width and shape of the lower die (normally the V-die) directly determine the inside radius of the bend and influence the amount of force required. A narrower V-die requires less tonnage but increases the risk of damaging the material, while a larger V-die is used for thicker materials and larger bend radius. The punch’s tip radius defines the bend's inner profile. Using the wrong combination can lead to inaccurate angles, surface marking, or even catastrophic tooling failure.

The actual bending process is where skill meets technology. The operator carefully positions the metal against the back gauge—a programmable stop that ensures each bend is made at the exact correct location on the sheet. The accuracy of this positioning is critical for the part’s overall geometry. On traditional machines, the operator would initiate the bend cycle, and the ram would descend to a predetermined depth to achieve a specific angle. However, modern CNC (Computer Numerical Control) press brakes have revolutionized this process.

CNC technology allows the operator to program the exact sequence of bends, the position of the back gauge, the ram’s descent, and the required pressure for each operation. Sensors can provide real-time feedback, and advanced machines can even automatically compensate for slight variations in the material’s thickness or spring-back. Spring-back is the elastic recovery of the metal after the bending force is removed; it causes the metal to try to spring back slightly toward its original shape. Experienced operators must over-bend the material to a greater angle to compensate for this phenomenon, a factor that is automatically managed by sophisticated CNC systems.

Finally, no discussion of press brake operation is complete without emphasizing safety. These machines exert immense force, capable of shearing metal and causing severe injury. Modern press brakes are equipped with light curtains, laser guarding, and two-handed controls that prevent operators from placing their hands in the danger zone during the bending cycle. Safety is not just a feature; it is an integral and non-negotiable part of the culture surrounding this powerful equipment.

The humble press brake is a masterpiece of industrial engineering. Moving from simple mechanical machines to today’s computer-controlled powerhouses, the essence of bending remains a dance between calculation, preparation, and execution. It is a process that transforms flat, inert sheets of metal into strong, functional, and complex forms, driving innovation and construction across countless industries. It is a testament to human ingenuity’s ability to shape the world, one precise bend at a time.