Email:info@ahsanxin.com Phone: +86-15655584855(WeChat) WhatsApp: +86-13013118515

| Availability: | |

|---|---|

| Quantity: | |

Hydraulic Synchronized

Sanxin

|

Product Description

1)

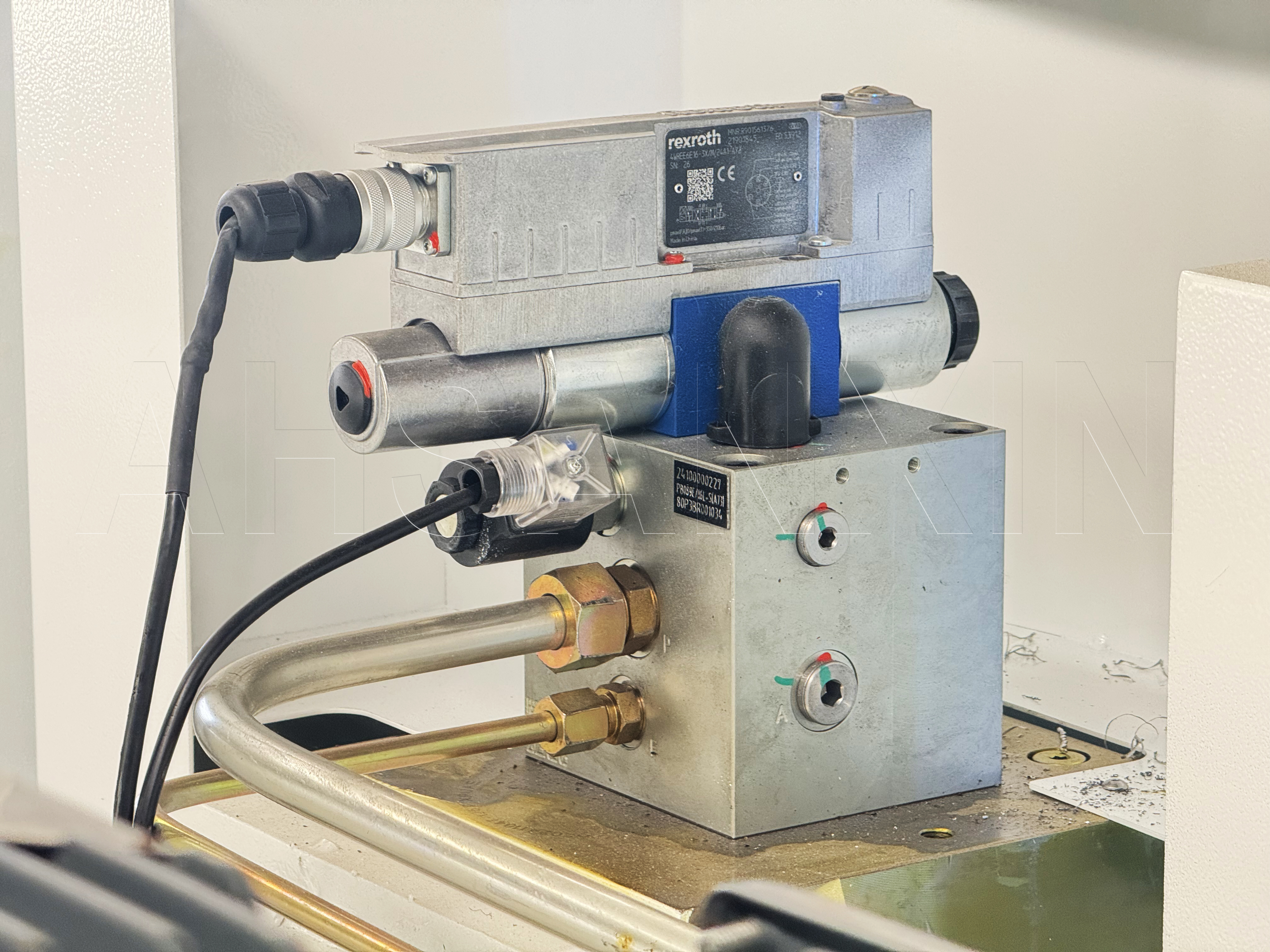

Sanxin PSB Servo CNC Press Brake adopts the Bosch-Rexroth proportional synchronous control system, with two gratings ruler installed on the C-shaped frame. The grating ruler, CNC system and proportional valve form a closed-loop servo control system to accurately control the speed and position of the slider.

2)

PSB CNC Press Brake adopts Innovance/Estun Servo main motor instead of Siemens main motor. The oil supply in demand, reduce overflow and energy saving 30~40%, prolong the life of hydraulic parts, reduce oil leakage and hydraulic problem, easy to use and maintanance. At the same time, servo main motor running with low noise, improving the working environment.

|Standards For Manufacture And Inspection:

• JB/T 2257.1-92 "Technical Requirements for Sheet Metal Bending Machines"

• JB/T 2257.2-1999 ''Sheet Metal Bending Machine Type and Basic Parameters''

• JB/T 50115-1998 ''Sheet Metal Bending Machine Reliability Assessment Method''

• GB/T 14349-2011 ''Sheet Metal Bending Machine - Precision''

|

Application Video

Sanxin PSB 11032K CNC Press Brake with Delem DA53T system 4+1 Axis

|Delem DA53T CNC Controller

• "Hot-key” touch navigation

• 10.1" high resolution colour TFT

• Up to 4 axes (Y1,Y2 + 2 aux. axes)

• Crowning control

• Servo and frequency inverter control

• TandemLink (option)

• USB memory stick interfacing

• 2D graphic programming(option)

Delem DA-53T Controller

Full touch screen control (PCT-touch)

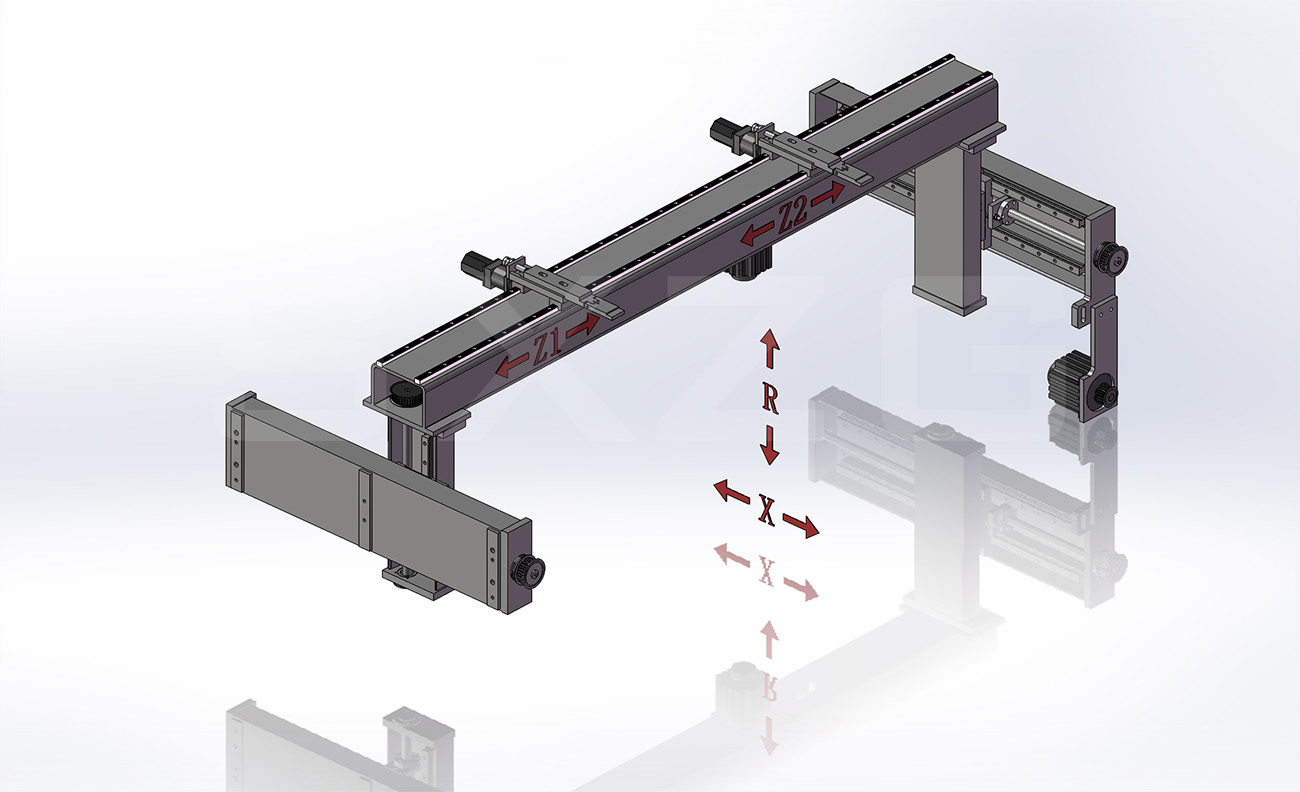

Backgauge

Standard backgauge X and R Axes

|Machine Details

DELEM DA53T

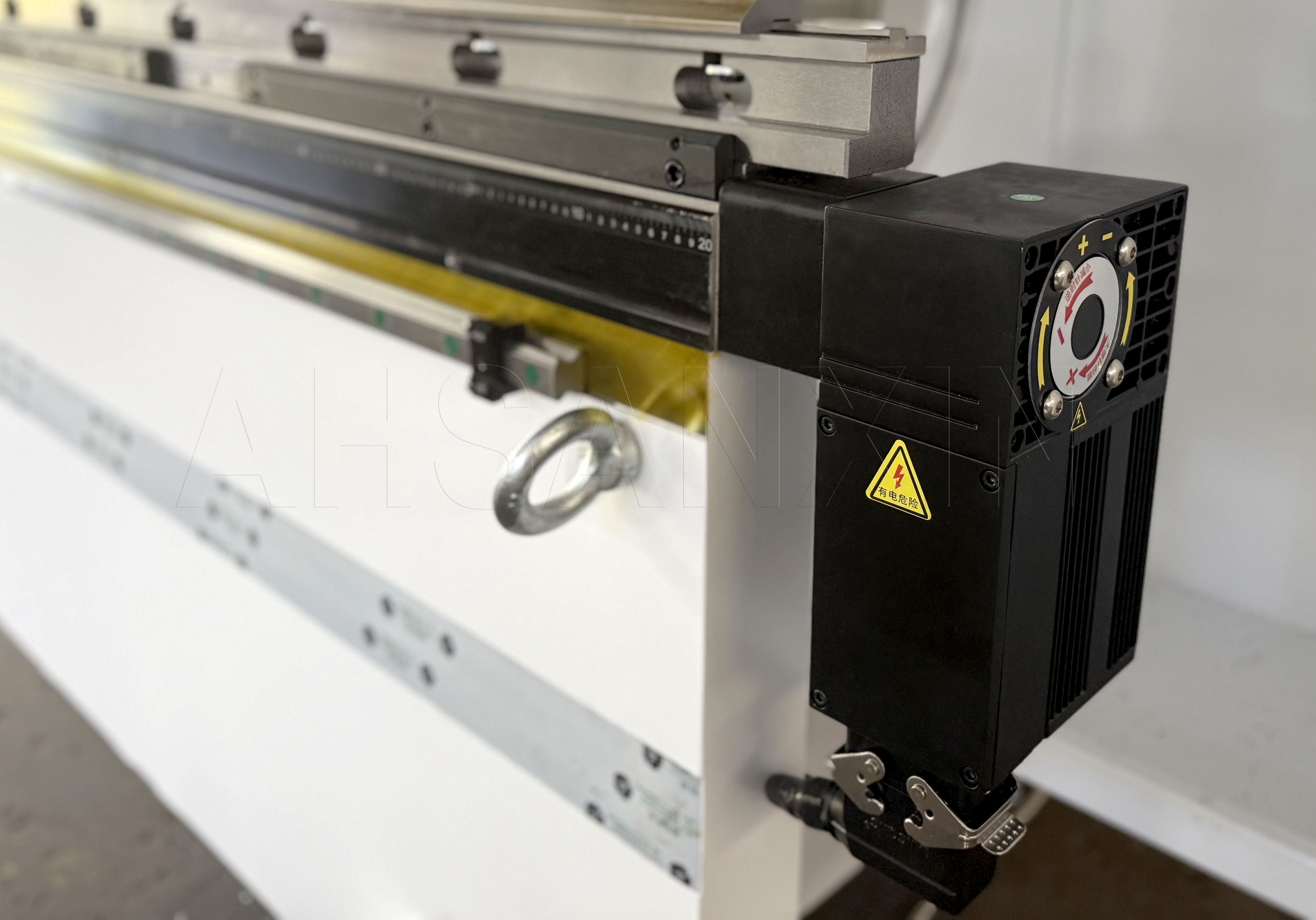

Fast clamping

Front support frame

Mechanical compensation

Backgauge

Electrical cabinet(Schneider Electric)

Bosch Rexroth (Germany)Hydraulic proportional valve

Spanish Fagor grating ruler

Estun Main Servo Motors

Stainless steel fuel tank

|Optional configuration

DSP Optical Safety Guards

ESTUN Mechanical arm

Backguage 6Axes--8Axes

CNC Follower Supports

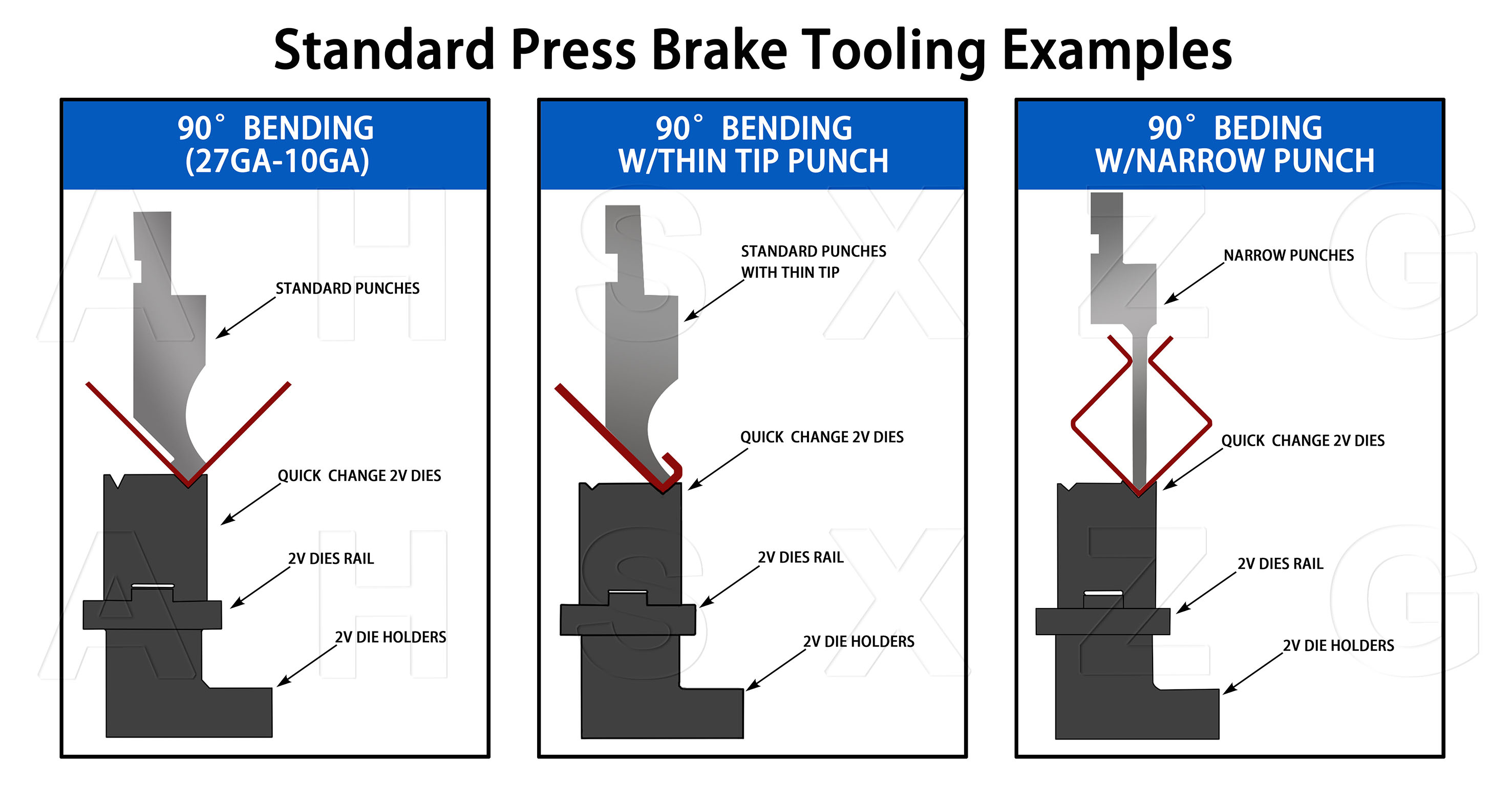

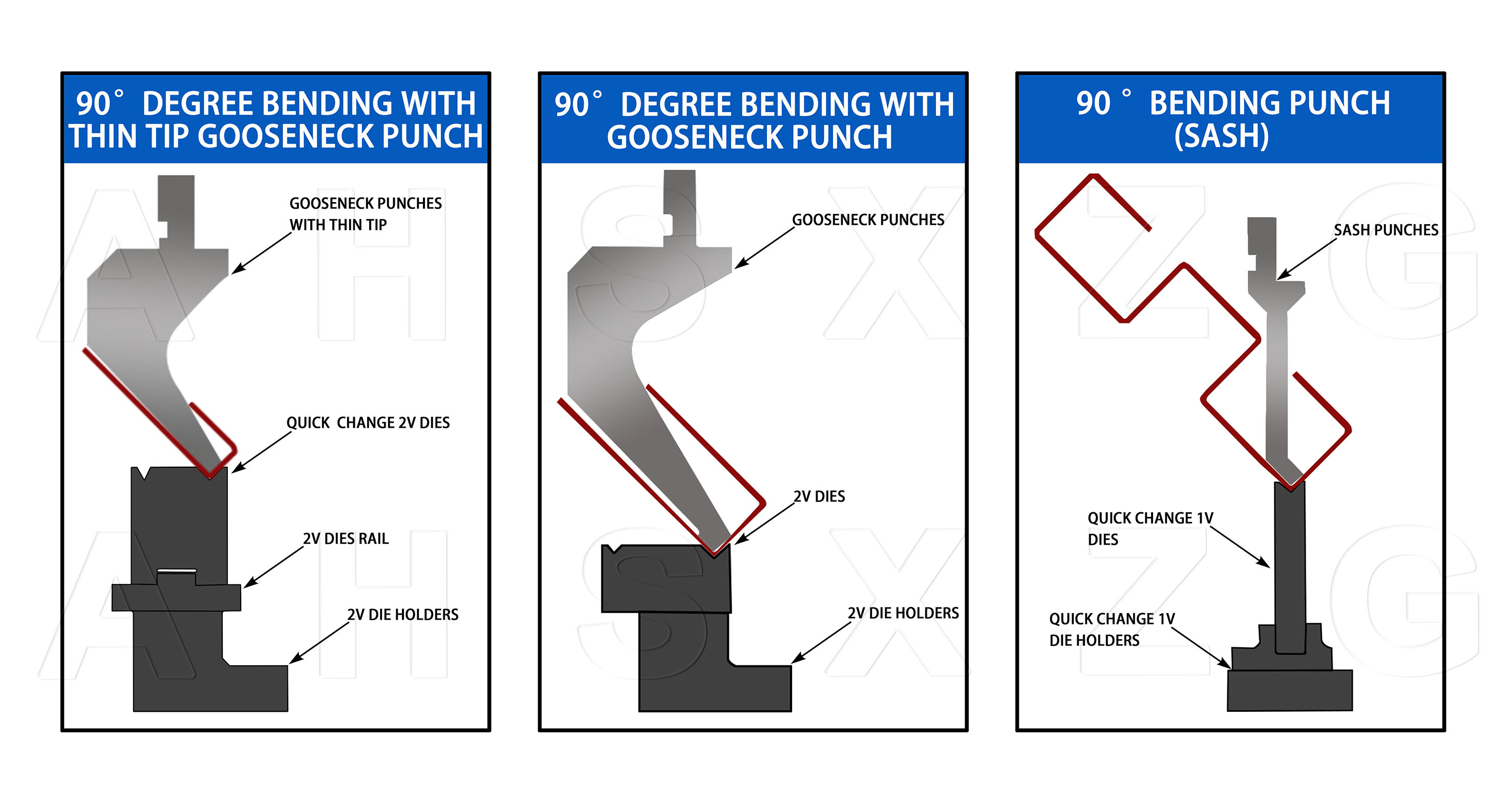

|Toolings

|Company Profile

1)Anhui Sanxin Heavy Industrial Machinery Manufacturing Co., Ltd is located in Bowang Economic Development Zone, Ma'anshan City, Anhui Province, China, and was established in 2007. Our company specializes in metalworking machines, including press brakes, shearing machines, rolling machinies, CNC grooving machines, and laser cutting machines, etc.

2)Our company has a strong team of professional mechanical engineers and assembly technicians who participate in design and research together. We also provide high-quality sales and after-sales services. We are modern well-known brand domestically and internationally.|

|Factory production process

|

Certifications

|Saize information

Model/Unit | Bending Force | Bending Length | Polo Distance | Throat Depth | Slide Strokes | Worktable Heght | Max Open Height | Servo Main Motor | Backgauge Travel | Speed | Dimension L*W*H |

Kn | Mm | Mm | Mm | Mm | Mm | Mm | Kw | Mm | mm/s | Mm | |

63T2500 | 630 | 2500 | 2100 | 350 | 150 | 780 | 420 | 5.5 | 600 | 200 | 3200*1600*2500 |

80T2500 | 800 | 3200 | 2700 | 350 | 150 | 780 | 420 | 7.5 | 600 | 200 | 3500*1600*2500 |

110T3200 | 1100 | 3200 | 2700 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 3500*1700*2700 |

110T4000 | 1100 | 4000 | 3500 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 4300*1700*2700 |

130T3200 | 1300 | 3200 | 2700 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 3500*1700*2700 |

130T4000 | 1300 | 4000 | 3500 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 4300*1700*2700 |

170T3200 | 1700 | 3200 | 2700 | 450 | 200 | 850 | 480 | 15 | 600 | 200 | 3700*1800*2800 |

170T4000 | 1700 | 4000 | 3500 | 400 | 200 | 840 | 480 | 15 | 600 | 200 | 4500*2200*3600 |

220T3200 | 2200 | 3200 | 2700 | 360 | 200 | 900 | 480 | 18.5 | 600 | 200 | 3700*1900*3000 |

220T4000 | 2200 | 4000 | 3500 | 400 | 200 | 900 | 480 | 18.5 | 600 | 200 | 4500*1900*3000 |

250T3200 | 2500 | 3200 | 2700 | 360 | 250 | 840 | 480 | 18.5 | 600 | 200 | 3800*1900*3100 |

250T4000 | 2500 | 4000 | 3500 | 400 | 250 | 900 | 550 | 22 | 600 | 200 | 4500*1900*3100 |

320T3200 | 3200 | 3200 | 2700 | 400 | 250 | 950 | 560 | 22 | 600 | 200 | 3800*2000*3200 |

320T4000 | 3200 | 4000 | 3500 | 400 | 250 | 950 | 560 | 22 | 600 | 200 | 4500*2000*3200 |

400T4000 | 4000 | 4000 | 3500 | 400 | 250 | 1000 | 560 | 30 | 600 | 200 | 4300*2200*3600 |

500T5000 | 5000 | 5000 | 3900 | 500 | 250 | 1000 | 600 | 37 | 600 | 200 | 5300*2300*360 |

500T6000 | 5000 | 6000 | 4900 | 500 | 250 | Sink800 | 600 | 37 | 600 | 200 | 6300*2300*3700 |

500T7000 | 5000 | 7000 | 5900 | 500 | 250 | Sink800 | 600 | 37 | 600 | 200 | 7500*2500*3700 |

600T5000 | 6000 | 5000 | 3900 | 500 | 300 | Sink800 | 600 | 45 | 600 | 200 | 5500*2700*3800 |

600T6000 | 6000 | 6000 | 4900 | 500 | 300 | Sink800 | 600 | 45 | 600 | 200 | 6500*2700*3800 |

600T7000 | 6000 | 7000 | 5900 | 500 | 300 | 1000 | 600 | 45 | 600 | 200 | 7500*2800*3900 |

|Product Packaging

Sanxin Press Brake Packaging

40HQ Container loading

Sanxin Press Brake loading

|Customer Photos

|Comment & FAQ

1. Are you trading company or manufacturer?

A: We are manufacturer of press brake, shearing machine, rolling machine and other sheet metal processing machines. Our company has more than 30 years of

production experiences.

2. How long is your delivery time?

A: The standard model is 15-30 days, the customized model is 30-60 days.

3. How to choose the model of machines?

A: Provide us the Max working area, the material and its thickness you want to bend/cut, we can help you to choose the best suitable machine.

4. What is your term of payment?

A: T/T, L/C, Western Union, Paypal, Alibaba Secure payment, etc. 30% deposit and 70% payment before delivery.

5. Where is your factory located?

A: Our company is in Maanshan, Anhui Province, which is only half an hour's drive from Nanjing Lukou Airport. If you visit our company, we will arrange a special bus to

meet you at the airport.

6. How does your factory do regarding quality control ?

A: Quality is priority factor for the development our cooperation 30 years. Also, we have CE and ISO certifications.