Email:info@ahsanxin.com Phone: +86-15655584855(WeChat) WhatsApp: +86-13013118515

| Sires: | |

|---|---|

| Availability: | |

| Quantity: | |

PSA Series

Sanxin

PSA

|

Product Description

Sanxin PSA series is a precision CNC-controlled press brake with crowing in a basic but very complete configuration, standard equipped with 4 CNC-controlled axes (Y1-Y2,X,V). PSA series offers the user a heavy built, reliable, precision CNC press brake at an economical price.

The high precision grating rulers at both sides of the machine continuously measure the movement and position of the upper beam (axes Y1-Y2).

The data is processed and monitored by the CNC controller which controls the hydraulic valves.

The high level of accuracy is obtained during the movement and final positioning of the upper beam due to the continuous monitoring and feedback of the encoder measuring data.

Using this technology, a repeatability of approximately 100% (+/-0.01mm) can be guaranteed.

|Application Video

Sanxin PSA 13032K CNC Electro-Hydraulic Press Brake

|Standard equipment

| CNC DELEM DA53T with 2D colour graphics |

| Rexroth (Bosch) hydraulic system |

| High efficiency motor – Siemens |

| Electrical cabinet with Schneider,Omron components |

| Fagor optical scales |

| Sanxin Pro Auto crowning system |

| Sanxin BGA-2 for X=550mm X,R-Axis |

| Tool kit: 2 V die (V=8-12) series of 835mm punches |

| Back guage with dust-proof cover |

| Heavy duty beam with linear guides for stop finger |

10.1" high resolution colour TFT

“Hot-key” touch navigation

Up to 4 axes (Y1,Y2 + 2 aux. axes)

Tool / material / product library

Advanced Y-axis control algorithms

for closed-loop as well as open-loop valves.

CNC Crowning control

USB memory stick interfacing

Profile-53TL offline software

|FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static

construction, stress and deformation for press brake and laser cutting machine

frames. So for complicated structures, highly complex loading’s, transient

modelling and combinations of the above, FEA makes sense.

|Electrical Cabinet

Sanxin CNC press brake electrical cabinets are fully fitted with Schneider Electric

components, delivering remarkable upgrades to equipment performance,

safety, and cost-efficiency.Schneider’s industrial-grade parts ensure stable, uninterrupted operation and minimal downtime. Featuring a modular design and global spare part availability,

Schneider components simplify maintenance, cut lifecycle costs, and support seamless system upgrades to meet evolving production needs.

|Rexroth Proportional Valves

High quality German hydraulic system with high frequency positioning

valves.

Smooth running of the machine is achieved with high speed machine

operation.

|Hydraulic Oil Tank

Hydraulic tank made of stainless steel, insuring a perfect clean hydraulic system.

According to our experience in after sales service, 85% of the problems with the

hydraulic system are caused by contamination of hydraulic circuit. Sanxin has

committed to reduce such failures and resolve this from the source by

implementation of our patented clean hydraulic system.

|Fagor grating ruler

Precision grating at both ends of the machine ensure highly accurate positioning of the upper beam.

The independently mounted ruler mounting frames automatically compensate for he minimal deflection of the press brake side frames, ensuring perfect bending results.

The ram accuracy is guaranteed to +/0.01mm.

|Crowning

Always provides an extremely consistent bending angle

Available with automatic drive systems

Mounted on the right-hand side as standard

Motorized adjustments provided for compensation by calculation of controller

Can effectively prevent the non-standard collision linear scale of the workpiece

Compact design which is practically maintenance free

|Punches & Dies

Selecting the appropriate press brake punches and dies is a crucial aspect to

consider before placing your order. The right combination of punch and die is

essential for achieving the desired bending shape. We offer a wide range of

tooling options tailored to meet the diverse bending requirements of our

customers.

|Moveable front support system

With the SPB Thin support system, you can bend thinner sheets and rely

on each toalways be correctly positioned and guided.This system is

installed in the fingers of theback gauge and can be activated with

predefined bending.This enables the plate toslide until it lies adjacent to

the back gauge.As a result, you can rely on.

|Motorized stop fingers

To ensure superior movement accuracy of the X-axis, we utilize imported ball

screws and linear guide rails instead of traditional screw rods. This choice

enhances the precision and consistency of our fabrication process.

We have implemented a synchronous pulley mechanism controlled by a

servo motor for the rear stop, as opposed to a stepping motor. This upgrade

provides better control and accuracy in our operations.

Our entire backgauge system undergoes a high-temperature tempering

process to eliminate internal stress, enhance metal plasticity and toughness,

and prevent any loss of accuracy resulting from frame deformation.

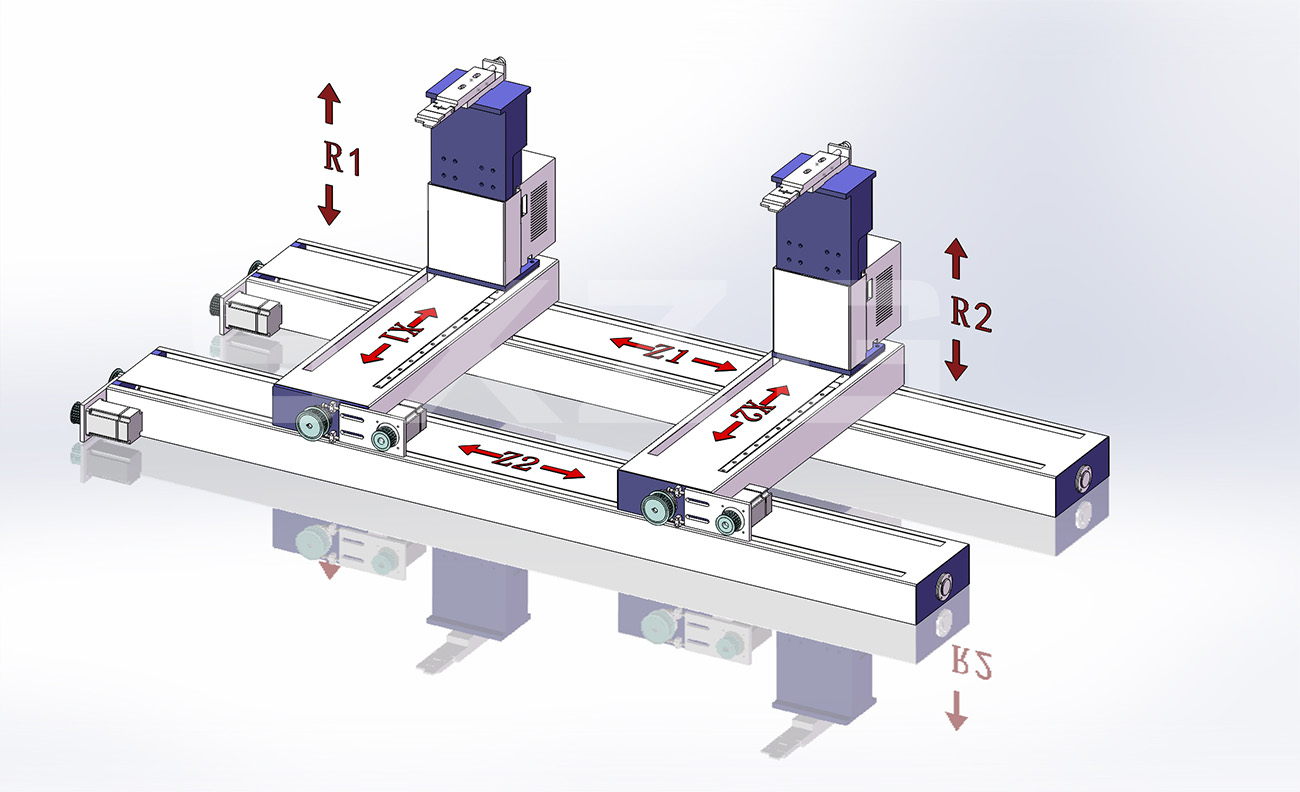

|Sanxin BGA-2 BackGauge

Press Brake 2-Axis CNC BackGauge With X,R-Axis

· Ball screws and double linear guide on X, R-axis

· Fingers on linear guides and micro adjustment.

· Mechanical accuracy ± 0.05 mm.

· Axes X speed 500 mm/s

· Axes R speed 500 mm/s

|Optional Surface

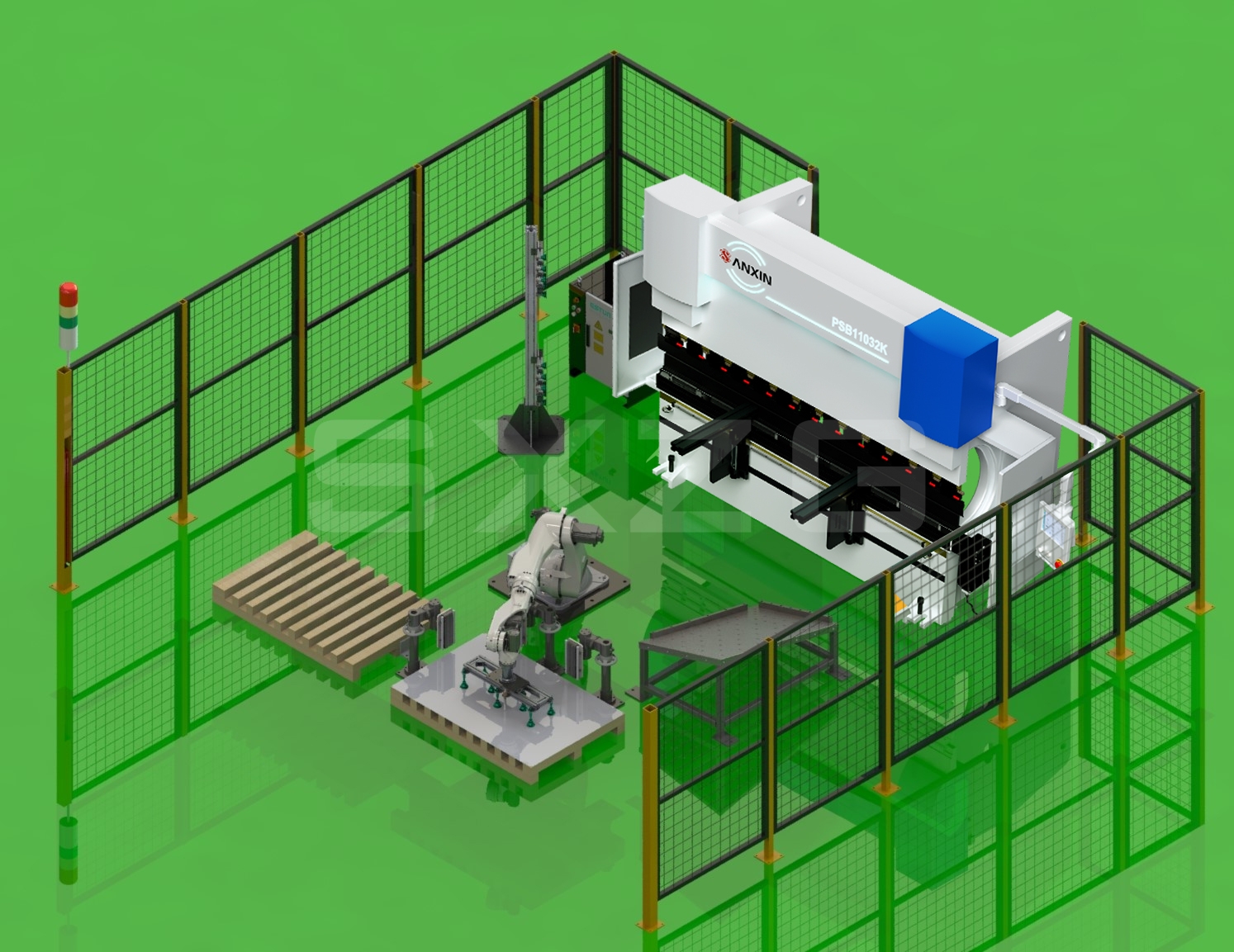

Robotic arm system

Multiple Axis back-gauge design

Laser Protection

|Technical Parameters

Model/Unit | Bending Force | Bending Length | Polo Distance | Throat Depth | Slide Strokes | Worktable Heght | Max Open Height | Servo Main Motor | Backgauge Travel | Speed | Dimension L*W*H |

Kn | Mm | Mm | Mm | Mm | Mm | Mm | Kw | Mm | mm/s | Mm | |

63T2500 | 630 | 2500 | 2100 | 350 | 150 | 780 | 420 | 5.5 | 600 | 200 | 3200*1600*2500 |

80T2500 | 800 | 3200 | 2700 | 350 | 150 | 780 | 420 | 7.5 | 600 | 200 | 3500*1600*2500 |

110T3200 | 1100 | 3200 | 2700 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 3500*1700*2700 |

110T4000 | 1100 | 4000 | 3500 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 4300*1700*2700 |

130T3200 | 1300 | 3200 | 2700 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 3500*1700*2700 |

130T4000 | 1300 | 4000 | 3500 | 500 | 200 | 780 | 480 | 11 | 600 | 200 | 4300*1700*2700 |

170T3200 | 1700 | 3200 | 2700 | 450 | 200 | 850 | 480 | 15 | 600 | 200 | 3700*1800*2800 |

170T4000 | 1700 | 4000 | 3500 | 400 | 200 | 840 | 480 | 15 | 600 | 200 | 4500*2200*3600 |

220T3200 | 2200 | 3200 | 2700 | 360 | 200 | 900 | 480 | 18.5 | 600 | 200 | 3700*1900*3000 |

220T4000 | 2200 | 4000 | 3500 | 400 | 200 | 900 | 480 | 18.5 | 600 | 200 | 4500*1900*3000 |

250T3200 | 2500 | 3200 | 2700 | 360 | 250 | 840 | 480 | 18.5 | 600 | 200 | 3800*1900*3100 |

250T4000 | 2500 | 4000 | 3500 | 400 | 250 | 900 | 550 | 22 | 600 | 200 | 4500*1900*3100 |

320T3200 | 3200 | 3200 | 2700 | 400 | 250 | 950 | 560 | 22 | 600 | 200 | 3800*2000*3200 |

320T4000 | 3200 | 4000 | 3500 | 400 | 250 | 950 | 560 | 22 | 600 | 200 | 4500*2000*3200 |

400T4000 | 4000 | 4000 | 3500 | 400 | 250 | 1000 | 560 | 30 | 600 | 200 | 4300*2200*3600 |

500T5000 | 5000 | 5000 | 3900 | 500 | 250 | 1000 | 600 | 37 | 600 | 200 | 5300*2300*360 |

500T6000 | 5000 | 6000 | 4900 | 500 | 250 | Sink800 | 600 | 37 | 600 | 200 | 6300*2300*3700 |

500T7000 | 5000 | 7000 | 5900 | 500 | 250 | Sink800 | 600 | 37 | 600 | 200 | 7500*2500*3700 |

600T5000 | 6000 | 5000 | 3900 | 500 | 300 | Sink800 | 600 | 45 | 600 | 200 | 5500*2700*3800 |

600T6000 | 6000 | 6000 | 4900 | 500 | 300 | Sink800 | 600 | 45 | 600 | 200 | 6500*2700*3800 |

600T7000 | 6000 | 7000 | 5900 | 500 | 300 | 1000 | 600 | 45 | 600 | 200 | 7500*2800*3900 |

|Product Packaging

|Production Process

Floor type gantry machining center

Boring and Milling machining center

CNC machining centers

|Certificate

|

1. Are you trading company or manufacturer?

A: We are manufacturer of press brake, shearing machine, rolling machine and other sheet metal processing machines. Our company has more than 30 years of production experiences.

2. How long is your delivery time?

A: The standard model is 15-30 days, the customized model is 30-60 days.

3. How to choose the model of machines?

A: Tell us the Max working area, the material and its thickness you want to bend/cut, we can help you to choose the best suitable machine.

4. What is your term of payment?

A: T/T, L/C, Western Union, Paypal, Alibaba Secure payment, etc. 30% deposit and 70% payment before delivery.

5. Where is your factory located?

A: Our company is in Maanshan, Anhui Province, which is only half an hour's drive from Nanjing Lukou Airport. If you visit our company, we will arrange a shuttle pick up to meet you at the airport.