Email:info@ahsanxin.com Phone: +86-15655584855(WeChat) WhatsApp: +86-13013118515

Views: 19 Author: Brian Gao Publish Time: 2025-08-29 Origin: Site

Press brakes have seen significant advancements in automation as technologies such as automatic tool changing cells, automated material handling and robotic bending have becoming increasingly common over the last decade.

However, for the most part, press brakes are still manually operated machines that require trained and skilled operators to achieve safe, efficient, and productive bending. Aside from bending parts, press brake operators are required to manage the setup and configuration of the machine safety and guarding devices and systems. An incorrect, or poor setup can not only result in a potential reduction in safety function but can also lead to a significant reduction in machine efficiency that results to lower productivity.

A press brake with an automated safety and guarding solution eliminates the need for manual adjustments to be performed by the operator by automatically driving the optical components to the correct position, then automatically making any necessary adjustments based on the tooling that had been installed. In addition, secondary processes automatically check and confirm the positioning and setup, thereby ensuring that the machine is always safe to operate.

Press brake technology

Reduce the workers’ impact, improving cost on operators

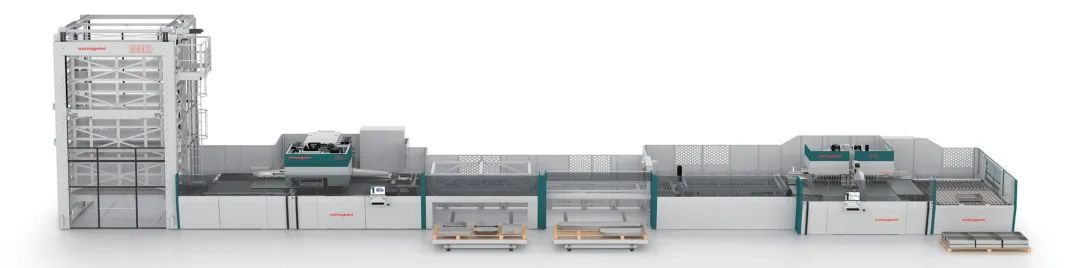

As labor costs continue to rise and errors and inefficiencies caused by manual operations become more prominent, more and more companies are beginning to seek automated solutions. In order to address these issues, the Salvagnini S4+P4 intelligent sheet metal flexible production line (Figure 2) saves labor costs and reduces the impact of human factors on product quality through full-process automation. The S4+P4 production line consists of the S4 punching and shearing composite center and the P4 multi-sided bending center, which can achieve one-stop stamping, shearing and bending processing. The entire process does not require human intervention, truly realizing "unmanned" lights-out production.

Figure2: Intelligent sheet metal plate flexible production line

Take an example of Changchun Zhucheng Group, a leading enterprise in the door industry. Before they introduced the Salvagnini S4+P4 sheet metal flexible production line, all door products were produced according to the traditional production method - a combination of manual and traditional machine tools. This not only requires a lot of operators, but also leads to unstable product quality. After introducing the Salvagnini equipment (Figure 3), they found that the sheet metal production that originally required 30 operators in two shifts now only requires one engineer for programming and operation, which greatly reduces labor costs. It is estimated that about 1.8 million yuan in labor costs can be saved each year. In addition, the first Salvagnini flexible production line introduced by Changchun Zhucheng Group in 2001 has been running smoothly for more than 20 years. It is still in full production every day and continues to create benefits for the company.

Zhucheng company bring two Salvagnini S4+P4 sheet metal flexible production line

At the same situation, a leading enterprise in electronic communication and EV industry Mianyang Chengjian group also benefits from the auto finish line solution provided by Salvagnini. Like shown in Figure 4. The introduction of Salvagnini equipment eliminated manual intervention in the sheet metal bending process of Mianyang Jiancheng Group, and replaced the previous production model that relied on the professionalism of operators to ensure product quality. Today, its products are automatically bent by Salvagnini multilateral bending centers, which not only ensures the consistency of product quality, but also greatly improves production efficiency. The efficiency of a Salvagnini P4 multilateral bending center is equivalent to that of 8 traditional bending machines, and the labor required is only 1/4 of that of traditional bending machines.

Figure 4: Salvagnini multilateral bending centers

Considering flexible production, efficiency and consistency

With the rapid advancement of technology, various industries are placing stringent demands on the precision, efficiency, and stability of metal processing. Traditional manual bending operations are not only inefficient and difficult to ensure consistent product quality, but also pose significant safety risks. The emergence of press brake automation has been a timely development, revolutionizing the metal processing industry. It not only significantly improves production efficiency and reduces labor costs, but also, with its high-precision and high-stability processing capabilities, meets the stringent quality standards of modern manufacturing, becoming a key force in driving industrial production towards intelligent and efficient processes.